Researchers Describe New Device to Digitize Chemical Processes

American Chemical Society | July 23, 2020

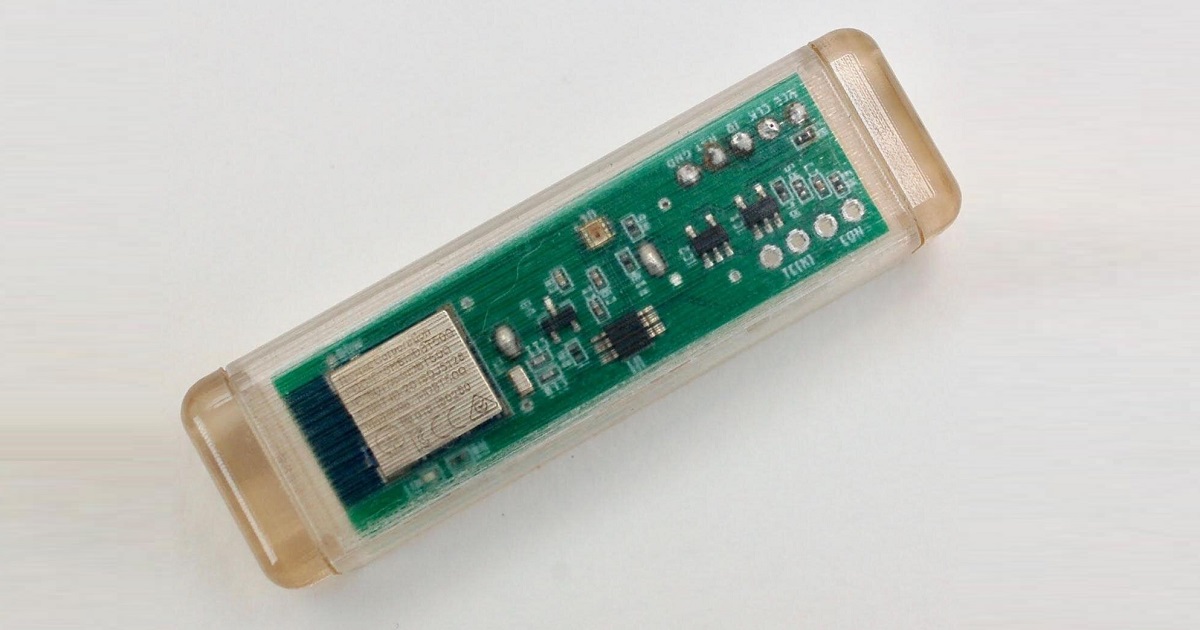

Miniaturized computer systems and wireless technology are offering scientists new ways to keep tabs on reactions without the need for larger, cumbersome equipment. In a proof-of-concept study in ACS Sensors, researchers describe an inexpensive new device that functions like a conventional magnetic stir bar, but that can automatically measure and transmit information on a solution's color, viscosity and a variety of other attributes to a smart phone or computer.

Automatic, remote data collection can make chemical processes more reliable, as well as less labor intensive and safer. This technology has begun to make inroads into chemistry labs, but options for scientists looking to remotely mix their reactions and monitor several parameters while those reactions occur remain quite scarce, limited and expensive. Nikolay Cherkasov, Dmitry Isakov and colleagues wanted to develop a device capable of simultaneously detecting numerous parameters using freely available open source software and easy-to-get, inexpensive components.