Braskem and Vartega Introduce Carbon Fiber Recycling Program for 3D Filament

VARTEGA, BRASKEM | May 20, 2021

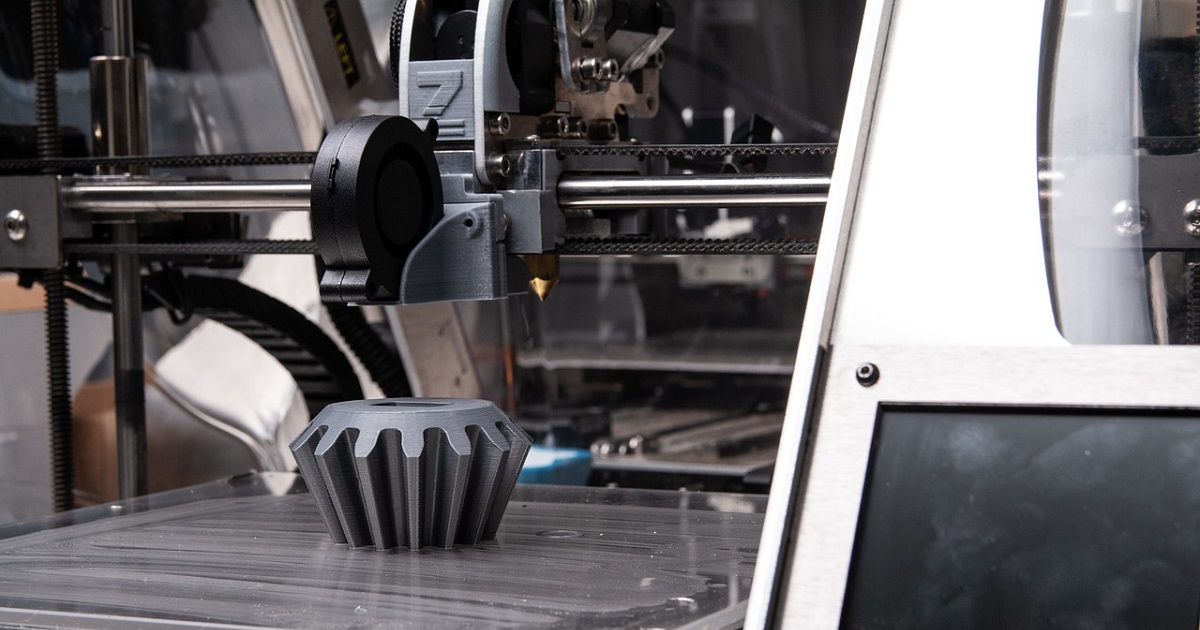

Braskem, the Americas' largest polyolefins producer and the world's biggest biopolymer producer, today announced an extended collaboration with Vartega Inc., a leading recycler of advanced materials, including carbon fibre reinforced plastics, for a new 3D Printing Filament Recycling Program. Braskem recently added new, advanced carbon fibre reinforced polypropylene filament for 3D printing ("CF-PP") to its 3D printing product line ("FL900PP-CF"). This product is made entirely of 100% recycled carbon fibre from Vartega and is designed to work with Braskem's polypropylene.Every box of Braskem's carbon fibre reinforced polypropylene filament will come with instructions on how to recycle the used carbon fibre filament through this programme. Every year, 24,000 tonnes of carbon fibre waste is disposed of in landfills.

Braskem is dedicated to a circular economy that is carbon neutral. Braskem pledged in 2018 to reuse, recycle, or recover 100% of plastic packaging by 2040. Braskem has announced new commitments to mitigate climate change, reduce plastic waste, and provide alternatives for recycled materials in its markets as part of its evolving sustainable growth policy.

Braskem's carbon fibre reinforced polypropylene filament has excellent mechanical and thermal properties, as well as low warpage, allowing users to 3D print lightweight, exceptionally rigid parts for high-end applications like automotive, aerospace, nautical, sporting goods, and more. Best of all, FL00PP-CF is made entirely of recycled carbon fibre and has the same efficiency as virgin carbon fibre.

Braskem is committed to moving towards a Circular Economy, where nothing is wasted and all is transformed, as the North American leader in polypropylene. Braskem announced last year that it had met its 2020 target of being a blue member of Operation Clean Sweep®. Braskem has joined the Polypropylene Recycling Coalition as a founding member and supporting partner, an effort of The Recycling Partnership aimed at increasing polypropylene (PP) curbside recycling access in the United States and ensuring PP is widely recovered and reused in end-markets such as food and beverage packaging, consumer products, and automotive. Braskem is also a member of the Alliance to End Plastic Waste, which was established in 2005.

ABOUT VARTEGA

Vartega is making carbon fiber more available to a wider range of industries by overcoming the world's most difficult advanced materials recycling challenges to build circular supply chains, decarbonize transportation, and enable a more sustainable future. The patented carbon fiber recycling method developed by the company scales quickly to fill a gap in the composites supply chain. Sporting goods, additive manufacturing, and vehicle lightweighting all use Vartega's carbon fiber and specialty thermoplastics.

ABOUT BRASKEM

Braskem is committed to contributing to the value chain in order to improve the Circular Economy, with a global view of the future focused on people and sustainability. Every day, the petrochemical company's almost 8,000 employees work to improve people's lives by developing sustainable chemicals and plastics solutions. Braskem has an innovative DNA and a large variety of plastic resins and chemical products for a wide range of industries, including food packaging, construction, manufacturing, automotive, agribusiness, healthcare, and hygiene. Braskem exports its products to clients in over 100 countries, with 41 manufacturing units in Brazil, the United States, Mexico, with Germany, and net revenue of US$13.2 billion.